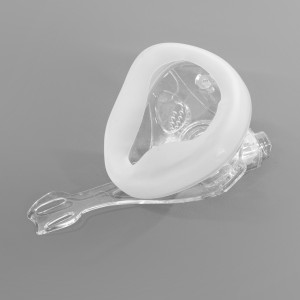

Musamman allura mold don lantarki roba sassa

Bayani

Yin gyare-gyaren allura hanya ce ta samar da sassa ta hanyar allurar abu a cikin wani tsari.Karfe (wanda aka fi sani da tsarin da mutu-casting), gilashin, elastomers, confections, kuma, mafi yawanci, thermoplastic da thermosetting polymers duk ana iya amfani da su wajen gyaran allura.Ana ciyar da kayan ɓangaren a cikin ganga mai zafi, gauraye, a tilasta shi a cikin wani rami mai laushi, inda ya yi sanyi kuma ya taurare zuwa tsarin rami.Bayan an ƙera samfur, yawanci ta mai ƙirar masana'antu ko injiniya, ana yin gyare-gyare daga ƙarfe, yawanci ƙarfe ko aluminium, kuma ana yin su daidai don ƙirƙirar fasalin ɓangaren da ake so.Kayan bugu na 3D kamar photopolymers waɗanda ba sa narkewa yayin yin allura na wasu ƙananan zafin jiki na zafin jiki ana iya amfani da su don wasu ƙirar allura masu sauƙi.Ana amfani da gyare-gyaren allura don samar da sassa daban-daban, daga ƙanana zuwa babba.Ƙarfin samar da sassa tare da nau'i daban-daban na geometrical da girma yana ƙayyade ta nau'in injin da aka yi amfani da shi a cikin aiki.

An saita shi don ware iska a cikin rami da iskar gas daga narkewar filastik yayin allura a cikin mold.Tsarin shaye-shaye na mutun filastik yawanci tashar iska ce mai siffar tsagi da aka gina a cikin mutu don fitar da iskar daga ramin asali da iskar gas ɗin da narkakkar ta shigo da ita. iska a cikin rami da iskar gas da narke ya kawo dole ne a fitar da shi zuwa waje na mold ta hanyar shaye-shaye tashar jiragen ruwa a karshen kayan aiki, in ba haka ba zai sa samfurori tare da pores, rashin haɗin gwiwa, mold cika rashin gamsuwa, har ma za a kona iskar da aka tara saboda yawan zafin jiki da ya haifar da matsawa.a karkashin yanayi na al'ada, za a iya samun iska a cikin rami a ƙarshen kwararar kayan da aka narkar da, ko kuma a cikin shimfidar wuri na mutu.

Na karshen shine tsagi mara zurfi tare da zurfin 0.03 - 0.2 mm da nisa na 1.5 - 6 mm a gefen mutu ... kayan da aka narkar da su za su kwantar da hankali da ƙarfafawa a cikin tashar a nan .. Matsayin budewa na tashar tashar jiragen ruwa bai kamata a jagoranci mai aiki ba don hana ƙaddamar da narkakkar kayan da aka yi ba da gangan. mashaya da rami mai fitar da wuta, da kuma tsakanin ƙwanƙolin ejector da samfuri da ainihin.